Marble is a timeless and exquisite material that has been treasured for centuries. From sculptures and monuments to countertops and flooring, its unique beauty and durability make is a popular choice for variety of applications. But what exactly is a marble and how is it formed? We are going to look into the science behind the marble in this blog, including its formation, qualities and the traits that make it such a valuable material.

Formation of Marble

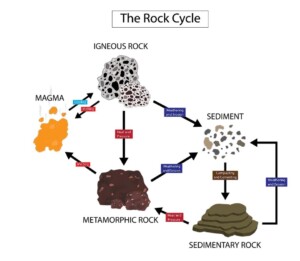

Marble is a metamorphic rock, which means that it’s formed from the transformation of existing rock types under the influence of heat, pressure and chemically active fluids. Marble is made from limestone or dolostone, sedimentary rocks primarily consist of calcium carbonate (CaCO3) in the form of the mineral calcite or dolomite (CaMg(CO3)2).

When limestone or dolostone is subjected to extreme heat and pressure for millions of years, the creation of marble formation take place deep within the Earth’s crust. Metamorphism is a process which causes the minerals in the rock to recrystallize. During the recrystallization process, the calcite or dolomite crystals increase and interlock, giving marble its distinct and homogeneous crystalline structure. The rocks density and strength increases with this change, making it more durable than its sedimentary precursor.

Characteristics of Marble

Marble’s appeal lies in its unique blend of aesthetic and physical characteristics. Here are some of the important characteristics that define this remarkable stone:

1. Colour and Veining

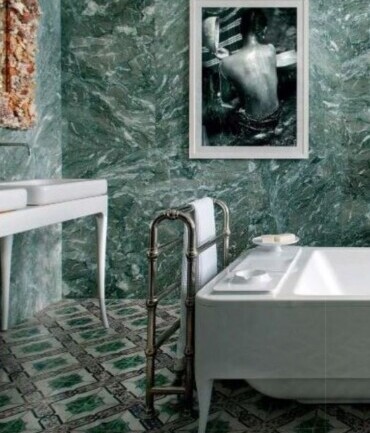

Marbles wide range of colour palette and veining patterns are one of the most noticeable qualities. Pure marbles are typically of white or light coloured, but the presence of various imperfections and mineral inclusions during marble formation can result in variety of colours, including shades like pink, green, blue, grey and black. The veining pattern formed by the distribution of these imperfections enhances the stone uniqueness and visual appeal. Any two slabs are not at all identical, making each slab a one of a kind work of nature.

2. Texture and Grain

Marble has a fine to medium grain texture and a smooth, sandy surface that can be polished to a high sheen. Marbles interconnecting crystalline structure contributes to its smoothness and glossy finish. This polished surface not only improves the stone’s aesthetics, but also it is easier to clean and maintain.

3. Hardness and Durability

While marble is softer than other stones like granite, it remains a durable material that is suitable for various applications. Marble normally ranks between 3 and 5 on Mohs hardness scale, indicating that it can be scratched by tougher things. However, with proper care and maintenance, marble surfaces can last for decades. Its density and heat resistance makes it an ideal choice for countertops, fireplaces and other high-traffic areas.

4. Porosity and Water Absorption

If marble is not properly sealed, it can absorb liquids and stains, as it is a porous material. Marble’s porosity varies according to the size of its crystal and composition. Using a high-quality sealer on marble surfaces on regular basis can prevent discoloration and etching on marble. By forming a barrier, this sealer keeps liquids and other materials from soaking into the stone.

Geological Occurrence and Extraction

Marble deposits are found all over the world, with large marble quarries located in countries like US, Italy, Greece, Turkey, India and other countries. The extraction process involves carefully removing the large blocks of marble from the marble quarry. They are then taken to processing facilities to be cut, shaped and polished into slabs or tiles.

1. Quarrying Process

The first step in the quarrying process is finding and assessing the marble resources. When a suitable deposit is found, the rock and dirt surrounded are removed to expose the marble. Large blocks of marble are then removed with the use of explosives, wire saws and drills with diamond tips. These blocks are cut into smaller, manageable pieces and sent to processing facilities.

2. Processing and Finishing

Block cutters or gang saws are used at the processing plant to cut marble blocks into slabs of different thicknesses. These slabs are then polished to achieve the desired finish, ranging from a high gloss to a matte or honed surface. Polishing brings out its natural beauty of the marble, highlighting its colours and veining patterns. Lastly, the finished slabs are rated according to its quality and sent to wholesalers and merchants.

How Different Stones Compare in Composition and Structure

Although marble remains one of the most admired natural stones, designers and architects often explore similar materials based on geological makeup and durability. At SPN Marble, clients looking for darker tones sometimes compare natural veining and surface hardness with premium stones priced alongside the Belgium black marble price, especially for wall cladding and artistic installations. For brighter colour palettes, many projects use white quartzite stone, valued for its crystalline structure and higher scratch resistance while still offering a marble-like appearance.

Traditional and heritage-style interiors often feature antique beige italian marble, appreciated for its soft texture and warm undertone that works well across flooring and staircase concepts. As trusted marble granite suppliers, SPN Marble helps customers understand how composition, porosity and polishing techniques affect long-term strength. With proper sealing and care, each natural stone can maintain its colour, gloss and density for decades, making selection easier for both homeowners and architects.